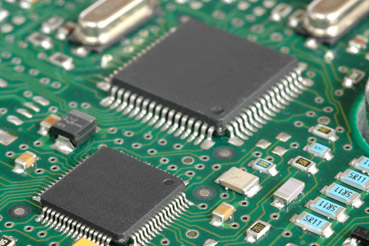

(Click on thumbnail to enlarge)

RoHS (Restriction of Hazardous Substances) Compliance Screening Testing is performed as the faster and sometimes nondestructive test method to verify that all products, components, consumer goods and homogenous base materials are in compliance with EU Directive 2011/65/EC (RoHS2). The RoHS compliance screening testing that is performed by JFP Technical Services, Inc., uses XRF analysis as the less expensive test method for verifying the RoHS compliance of all products and components to be sold. This test method verifies the five (5) restricted elements, following IEC 62321-2 and IEC 62321-3-1.

This RoHS Compliance Screening test provides three (3) possible results: PASS, FAIL, or INCONCLUSIVE. An INCONCLUSIVE result when using the XRF test method may occur when the amount of the restricted element is above 80% of the specified limit, possibly requiring additional testing, or to identify the element’s form in the product, at additional cost.

A test report will be provided listing the amounts of the restricted elements found for each material tested for that product or component.

Cost of the RoHS compliance screening varies depending on the product or material to be tested. There is an added cost for de-construction of a product or component, if needed. Discounts are available when three (3) more tests are performed at the same time, as part of the same purchase order. A test is defined as the testing of any or all base or homogeneous materials that are part of the same product or component. Base PRice starts at $100.00 minimum.

Call for a quote today.

RoHS screening testing is performed to verify that the composition of components or materials used in a product meet the requirements of the European Union (EU) Directive 2011/65/EC, Restriction of Hazardous Substance (RoHS2), which limits the amounts of five (5) specific elements in products and materials sold in the EU, China, parts of the USA, and other countries. The restricted elements are: Lead, Mercury, Hexavalent Chromium, Cadmium and Bromine in compounds PBDE and PBB, which all have specific health effects and long term environmental effects. Hexavalent Chromium (Cr+6) is restricted to the specified limit, but Metallic and Trivalent Chromium (Cr+3) are acceptable and excluded.

The RoHS directive requires that all of the homogeneous base materials used in a product are to be tested, to insure that each material used meets these requirements. This means that products with many components, coatings, or materials will need to be disassembled or de-constructed to be able to test all of the homogeneous base materials, which will be at additional cost, depending on the complexity.

The initial RoHS compliance testing is usually performed by the raw material or original component manufacturers to verify that their products meet the EU Directive requirements, usually using costly test methods. These suppliers will then provide a “Certificate of Compliance” (CoC) to the purchaser of their material. These CoC’s are to be kept on file for each product, material or component purchased, and filed by heat, lot, PO, etc….

The RoHS directive requires that there is active participation at all levels of a product’s life, requiring all parties invovled with the manufacturing of a product to perform their “Due Diligence” in assuring the EU directive is being met. The RoHS compliance screening testing provided by JFP Technical is performed to help the manufacturers meet the “Due Diligence” requirements.

To perform “Due Diligence” it is required that a manufacturer who received a product or material from a vendor or supplier submitting a CoC stating that the product meets the RoHS requirements, that the manufacturer is required to take some action to verify that the vendor’s or supplier’s CoC’s are correct. To do this it is suggested to take a random sampling of materials or components received from that vendor or supplier, and verify that the CoC is accurate. This can be done by performing the RoHS Compliance Screening test to verify that the material or product meets the RoHS requirements. This sample testing is suggested to be performed on a regular basis (EX.: every 6 or 12 months for each supplier), and these verthe receiving manufacturer is required to take a random sampling of the materials or components received from that supplier, and verify that the CoC is accurate. This testing is to be performed on a regular basis (Ex.: every 6 or 12months for each supplier), and these test results are then filed with the supplier certifications.

This RoHS compliance screening testing is also required when a manufacturer performs any additional processing that may change the original material or component, in any way.

Components that do not have a CoC should always receive a RoHS compliance screening test.

Please call JFP Technical for assistance with RoHS Compliance Screening Testing.

RoHS Compliance Screening Testing Specifications

- General Capabilities

-

RoHS Calibration

Meet Due Diligence

Verify

Sample Testing

- Analytical Testing

-

Possibly Non-destructive

Possibly Destructive

May need de-construction

Portable on-site testing

XRF chemical analysis

- Testing Results

-

Pass

FailInconclusive – Additional testing needed

- Screening

-

Mercury (Hg)

Lead (Pb)

Cadmium (Cd)

Chromium (Cr)

Hexavalent Chromium (Cr+6)Bromine (Br)

– Polybrominated Biphenyls (PBB)

– Polybrominated Diphenyl Ethers (PBDEs)

Additional Information

- Industry Standards

-

RoHS

RoHS2

EU Directive 2011/65/ECIEC 62321-2

IEC 62321-3-1