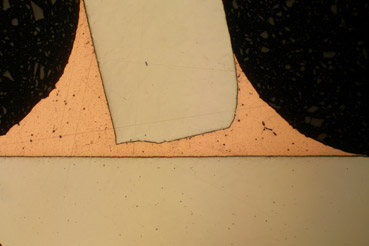

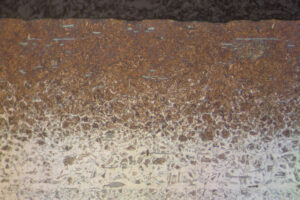

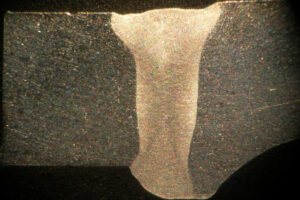

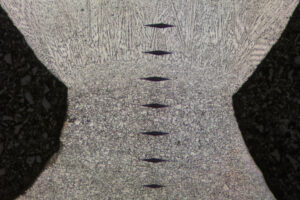

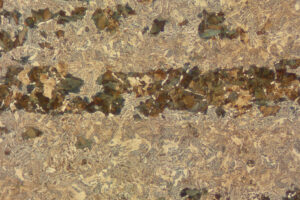

(Click on thumbnail to enlarge)

Metallurgy:

Metallurgy is the material science that studies the physical and chemical behaviors of the metallic elements, their intermetallic compounds, and their mixtures, which are used to make metal alloys. Metallurgy is also the technology of metals: the way in which science is applied to the production of metals, and the engineering of metal components through thermal and forming processes, so they can be used to meet the physical needs in developing products for consumers and manufacturers.

Metallography:

Metallography is the study of the physical structure and components of metals and other materials, typically using microscopy to study the microstructure and the effects of the thermal, forming, joining and other manufacturing processes used to make the metal or material fit for use in a product, or help in the examination on why a metal failed.

Metallurgical Analysis:

Metallurgical analysis includes the sample preparation methods used to prepare metal and other material samples for analysis; and the many test methods used to evaluate and document the metal and other material samples for suitability for use in its intended application.

Metallography and Metallurgical Analysis Services:

- General Capabilities:

-

Metallurgical Analysis of Materials

- Types of Analysis:

-

Comparative Analysis Between Materials

Comparative Analysis Between Processes

Competitor Analysis

Customer Requirements

Defect Analysis

Design Review

Failure Analysis

First Article Inspection

Heat Treat Response

Material Research

Process Development

Process Verification

Bond Analysis

Plating Thickness

Quality Assessment

Quality Control

Weld Evaluations

Reverse Engineering

Substantiation Analysis of Welds or other Processes

Third Party Verification

And Many More Applications

- Materials Analyzed:

-

Alloy Steels

Aluminum and Aluminum Alloys

Brasses

Bronzes

Carbon Steels

Cast Irons

Cast Steels

Castings

Ceramics

Copper and Copper Alloys

Crimps

Ductile Iron

Forgings

Gray Iron

High Temperature Alloys

HSLA Steels

Lead and Lead AlloysNickel Alloys

Plastics and Rubbers

Plating and Coatings

Powder Metals

Printed Circuit Boards

Solder Joints

Stainless Steels

Super Alloys

Titanium

Tool Steels

Weldments

Wrought Metals

Zinc

And Many other Materials

- Metallographic Analysis –Sample Prep Methods:

-

Collection of Residues, Corrosion, Debris As-Needed

Cleaning of Sample as Needed

Cross-Sectioning the Area of Interest so It can be Mounted (Abrasive, Diamond, or Band Saws)

Dimensional Inspection As-Needed

Documentary Photographs As-Needed

Etching

Grinding

Hardness Testing

Macroscopic or Stereomicroscopic Inspection

Microscopic Inspection

Macro Etching

Mounting

Polishing

Research

Sectioning the Area of Interest

SEM Analysis As-Needed

Testing

Visual inspection

XRF analysis as-needed

And Many other Steps as Needed

- Metallurgical Analysis – Testing Methods:

-

Bainite

Banding

Braze Joints

Cable to Terminal Electrical Crimp Analysis by Cross-Section and Measurements

Carbides

Carburization

Case Depth

Chemical Analysis

Cracks, Secondary Cracks, and Microcracks Depths

Crimping and Staking Analysis

Decarburization

Diffusion Depth and Penetration

Dimensional Measurements

Effective Case Depth

Ferrite

Flow Lines

Fracture Surface Analysis

Grain Boundaries

Grain Direction

Grain Growth

Grain Size

Graphite Flake Type Analysis and Determination

Heat-Affected-Zone (HAZ)

Heat Treat Analysis

Image Analysis

Inclusions and Inclusion RatingsMartensite

Metallurgical Analysis and Evaluation

Microhardness Testing

Microphotographs

Microstructure Analysis

Nodularity

Optical Microscopy

Oxides, Oxidation

Pearlite

Plating, Coating, or Layer Thickness Measurement

Re-Carburization, Carbon Restoration

Retained Austenite

Rolling Direction

Scanning Electron Microscopy (SEM) Analysis

Segregation

Spheroidization

Solder Joint Analysis

Substantiation of Weld Dimension and

Surface Condition Analysis

Surface Hardening

Total Case Depth

Weld Penetration and Fusion and Dimensional Analysis

White Layer

Witness Line Determination

XRF Analysis

And Many More Specialized Tests

- Replica & Replication Testing:

-

Bainite Presence

Bearing Races

Grain SizeJet Engine Components

Microstructure Analysis

Tubing and Pipes

- Hardness Testing Services:

-

Rockwell Hardness Scales: A, B, C, D, E, F, L, M and R

Superficial Rockwell Scales: R15N, R30N, R45N, R15T, R30T, and R45T

Portable Superficial Rockwell Hardness Testing: RC, RA, RB, HV (Vickers), RE, HB/3000, HB/500

Ultrasonic Hardness Testing: RC and HV (Vickers)

Brinell Hardness (BHN) (HB): 500Kg, 1500Kg, 3000Kg

Tele-Brinell Hardness Testing (BHN) (HB)Knoop Microhardness: HK 50 grams to 500 grams

Vickers Microhardness: HV 50 grams to 500 gramsDurometer Hardness Testing of Plastics, Foams, and Rubbers – Scales: A, D,

Wallace Micro Durometer: IRHDComparison Hardness using Files

Sorting of Mixed Material